Glass Bottle Manufacturing Process

Glass Bottle

Manufacturing Process

·

Type I - Borosilicate Glass

·

Type II - Treated Soda Lime Glass

·

Type III - Soda Lime Glass

The materials used to

make glass include approximately 70% sand along with a specific mixture of soda

ash, limestone and other natural substances – depending on what properties are

desired in the batch.

When manufacturing soda lime glass, crushed, recycled glass, or cullet, is an

additional key ingredient. The amount of cullet used in the batch of glass

varies. Cullet melts at a lower temperature which reduces energy consumption

and requires fewer raw materials.

Borosilicate glass should not be recycled because it is heat-resistant glass.

Because of its heat resistant properties, borosilicate glass will not melt at

the same temperature as Soda Lime glass and will alter the viscosity of the

fluid in the furnace during the re-melt stage.

All of the raw materials for making glass, including cullet, are stored in a

batch house. They are then gravity fed into the weighing and mixing area and

finally elevated into batch hoppers that supply the glass furnaces.

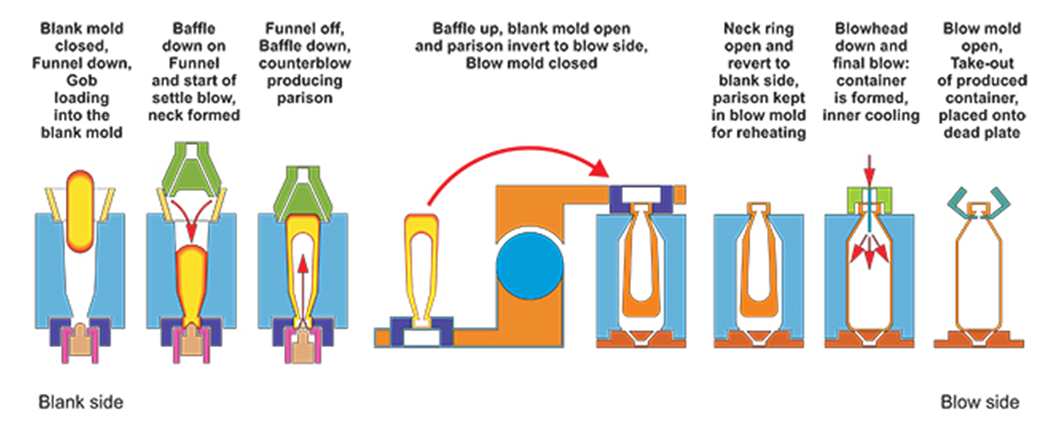

Blown Glass is also known as molded glass. In creating blown

glass, gobs of heated glass from the furnace are directed to a molding machine

and into the cavities where air is forced in to produce the neck and general

container shape. Once they are shaped, they are then known as a Parison. There

are two distinct forming processes to create the final container:

·

Blow & Blow Process - used for

narrow containers where the parison is formed by compressed air

·

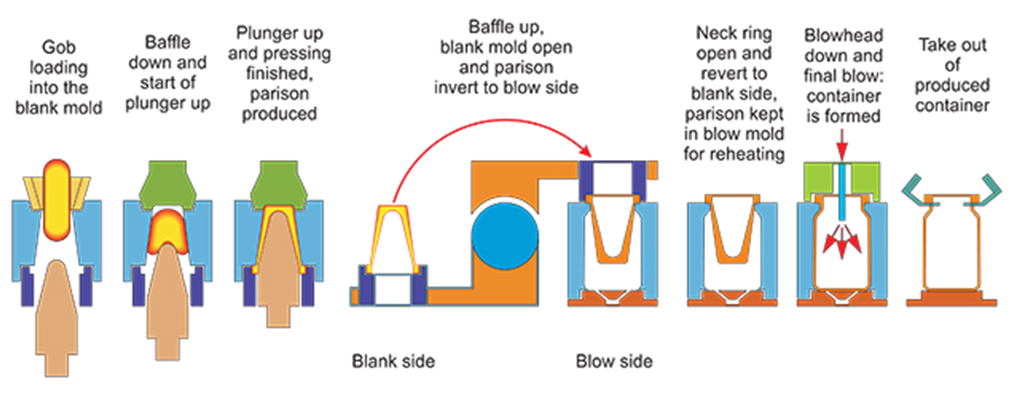

Press & Blow Process- used for large

diameter finish containers in which the parison is shaped by pressing the glass

against the blank mold with the metal plunger

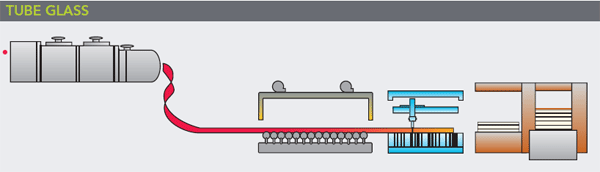

Tubing Glass is formed by a continuous draw process using either

the Danner or Vello processes to achieve the correct diameter and thickness.

The glass is drawn over a line of support rollers by a drawing machine.

·

Danner Process - glass flows from a furnace

forehearth in the form of a ribbon

·

Vello Process - glass flows from a furnace

forehearth into a bowl which is then shaped

Blow and Blow Process - compressed air is used to form the

gob into a parison, which establishes the neck finish and gives the gob a

uniform shape. The parison is then flipped to the other side of the machine,

and air is used to blow it into its desired shape.

Press and Blow Process- a plunger is inserted first, air then

Press and Blow Process- a plunger is inserted first, air then

follows to form the gob into a parison.

At one point this process was typically used for wide mouth containers, but

with the addition of a Vacuum Assist Process, it can now be utilized for narrow

mouth applications as well.

Strength and distribution is at its best in this method of glass formation and

has allowed manufacturers to “lightweight” common items such as beer bottles to

conserve energy.

Conditioning - no matter the process, once the blown glass

containers are formed, the containers are loaded into an Annealing Lehr, where

their temperature is brought back up to approximately 1500° F, then reduced

gradually to below 900° F.

This reheating and slow cooling eliminates the stress in the containers.

Without this step, the glass would easily shatter.

Surface Treatment - external treatment is applied to

prevent abrading, which makes the glass more prone to breakage. The coating

(usually a polyethylene or tin oxide based mixture) is sprayed on and reacts on

the surface of the glass to form a tin oxide coating. This coating prevents the

bottles from sticking to one another to reduce breakage.

Tin oxide coating is applied as a hot end treatment. For cold end treatment,

the temperature of the containers is reduced to between 225 and 275° F before

application. This coating can be washed off. Hot End treatment is applied

before the annealing process. Treatment applied in this fashion actually reacts

to the glass, and cannot be washed off.

Internal Treatment - Internal Fluorination Treatment

(IFT) is the process that makes Type III glass into Type II glass and is

applied to the glass to prevent bloom.

Quality Inspections - Hot End Quality Inspection

includes measuring bottle weight and checking bottle dimensions with go no-go

gauges. After leaving the cold end of the lehr, bottles then pass through

electronic inspection machines that automatically detect faults. These include,

but are not limited to: wall thickness inspection, damage detection,

dimensional analysis, sealing surface inspection, side wall scanning and base

scanning.

To learn more about Lab Glass Defects & How to Inspect Glass Packaging,

please click here to

read more and download a reference guide to help determine whether or not you need

to be concerned with a defect.

Examples of Blow & Blow Containers

Examples of Press & Blow Containers

·

Graduated Medium Round Bottles

Danner Process

·

Tubing sizes from 1.6mm to 66.5mm diameter

·

Drawing rates of up to 400m a minute for the smaller

sizes

·

Glass flows from a furnace fore hearth in the form of a

ribbon, which falls on to the upper end of an inclined refractory sleeve,

carried on a rotating hollow shaft or blowpipe.

·

The ribbon is wrapped around the sleeve to form a smooth

layer of glass, which flows down the sleeve and over the tip of the shaft.

·

The tubing is then drawn over a line of support rollers

by a drawing machine situated up to 120m away.

·

The dimensions of the tubing are determined as the glass

cools through its setting point at the unsupported section between the blowpipe

and the first line roller.