-

Home

-

About Us

-

Products

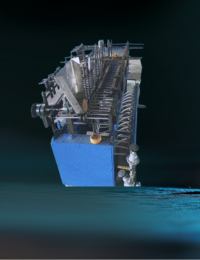

- Vertical Glassware Making Machine

- Automatic Tube Feeder

- Electrical/Gas Annealing Oven

- Glassware Inspection Machine

- Glass Tube Machine

- Horizontal Galssware Machine

- Glass Beaker Machine

- Horizontal Ampule Machine

- The Glassware Printing Machine

- Glass Tube Cutting Equipment

- Condom Glass Mold Shaping Machiner...

- Ampoule Ink Printing Machine

- Glassware Annealing Furnace

- Glass Pipette Production Line

- Glass Pipette Pasteur Machine

- Glass Expansion Tubing Machine

- Glass Tube Annealing Furnace

- Glass Measuring Cylinder Machine

- Petri Dish Making Machine

- Automatic Glass Joint Machine

- Industrial Glass Storage Machine

- Other Custom Glass Container Lines

- Other Glass Containers Inspection ...

-

Application

-

Guide

-

News

-

Contact Us