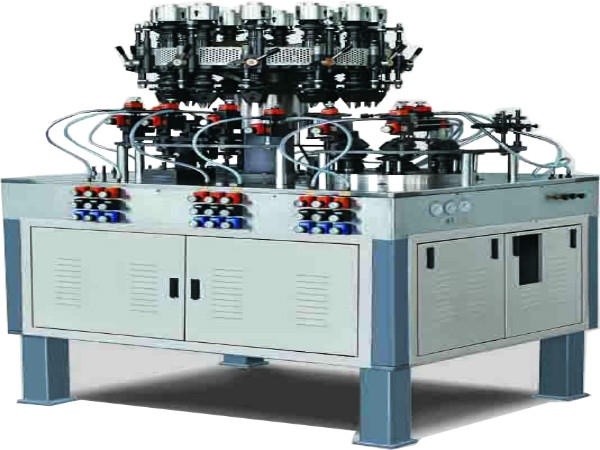

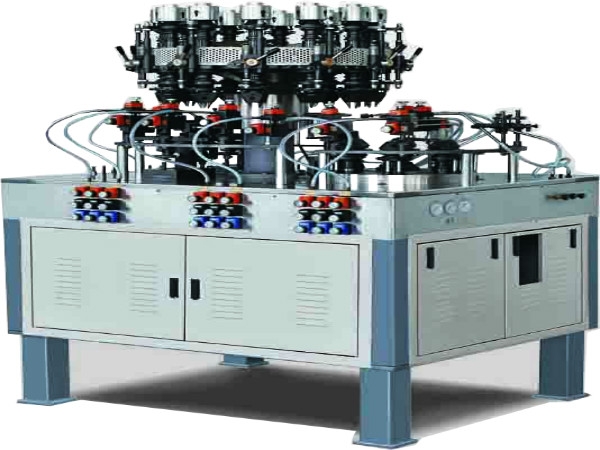

ZP30-32 is suitable for producing glass vials with dia.14mm-30mm. Part A adopts double chuck design. This design decreases the shakiness and increases the stability of glass tubes, and improves the quality of glass vials.

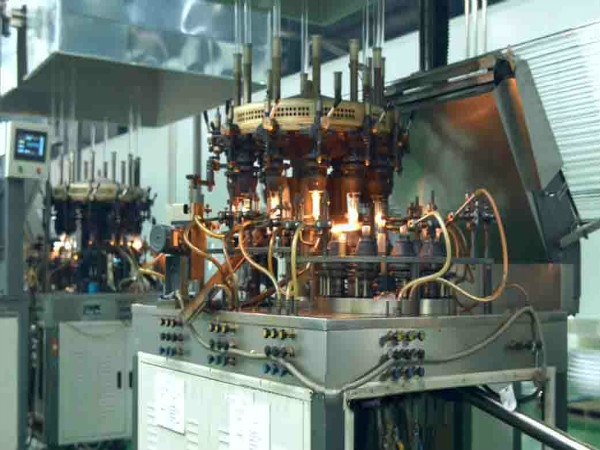

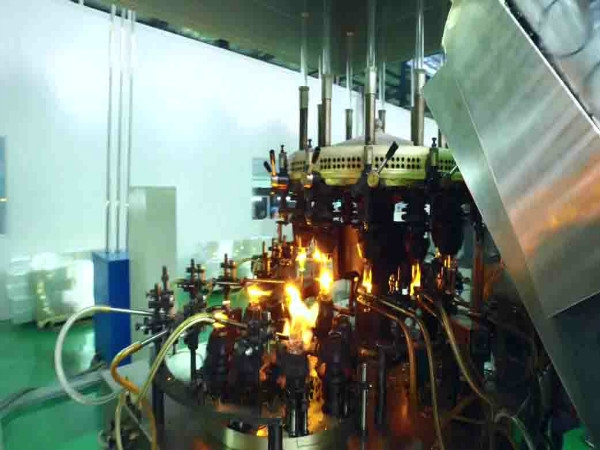

Introducing the ZP64CW, a groundbreaking innovation in vial manufacturing! We‘re proud to be the pioneers behind the world‘s first 16-head and 32-head servo fully digital vial machines. Designed for high-speed production of large batches, the ZP64Cw boasts 32 stations in Part A and 22 stations in Part B. It‘s the ultimate solution for efficient vial forming. Stay ahead in the industry with our cutting-edge technology.

Introducing the ZP30-32, a game-changing innovation in vial manufacturing! Our 12-head Double-chuck Vial-making Machine stands out as a cutting-edge solution in the industry. With its advanced features and precision engineering, it‘s designed to streamline vial production and boost efficiency.

This machine model is suitable for manufacturing glass bottles with a diameter ranging from 14mm to 30mm. Part A is equipped with two sets of clamps, one above and one below, which reduces the glass tube‘s wobbling during production, enhances its stability, and improves product quality.

Our 12-head dual-clamping bottle-making machine stands out in the industry as a cutting-edge solution. With its advanced features and precision engineering, it aims to simplify the bottle manufacturing process and enhance efficiency.

In accordance with European and American linguistic conventions, this translation emphasizes clarity and directness.